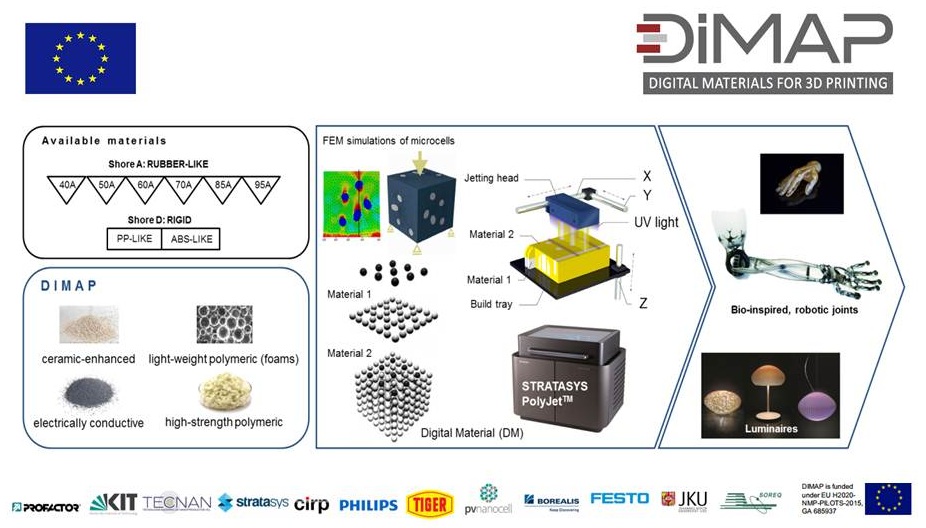

One of the most relevant technologies of additive manufacturing is PolyJet, because it is able to carry out rapid manufacturing processes generating final products with a high resolution of microscopic layer and an extremely good accuracy of around 0,1 mm. The main defiance of this technology is that due to the physical-chemical properties of its current materials, its most applications are focused on prototyping models and not directly on obtaining end-use products for final industrial sectors. In this context, the emergence of DIMAP project based on the development of novel nanoparticles enhanced digital materials for 3D printing and their application in both robotic and electronic industries is completely a challenge. Concretely, DIMAP project pretends to achieve new multi-material systems for 3D-inks based on ceramic enhanced materials, electrically conducting materials, light-weight polymeric materials and high-strength polymeric materials with the purpose of improving mechanical properties, electrical conductivity and weightiness of previous 3D-materials. All these new materials with advanced functionalities will be demonstrated and validated during this project by their incorporation in Polyjet printers for the production of two types of functional demonstrators as are soft robotic arms/joints and customised luminaires. Moreover, and due to the high environmental and human health awareness that this project shows, both material and printer developments will be aimed by a safe design.

DIMAP project is a 3 year research funded by the EU Framework Programme for Research and Innovation: Horizon 2020 (EU-H2020-NMP-PILOTS-2015-GA-685937), and it brings together European experts from all aspects of the fabrication supply chain. The following scheme shows an overall approach of this Project.